Reference Price:

Get Latest Price

Input Size

<40mm

Output Size

0.015-0.25mm

More than 200 kinds of materials

Production capacity 12-1000 t/h

Max Input Size 35-300mm

Discharging Range 3-60mm

Processing Material: stone,rocks,pebble,limestone,calcite, granite, quartz, dolomite, slag, iron ore, copper ore, gold ore, coal gangue,basalt and other minerals.

Email:sales@zdzg.com (contact us by one of the three ways)

Email: sales@zdzg.com (contact us by one of the three ways)

Zhongde Heavy Industries Co., Ltd. China(Mainland)

Response Time <24h

Factory Price 100%

Online Service 24h

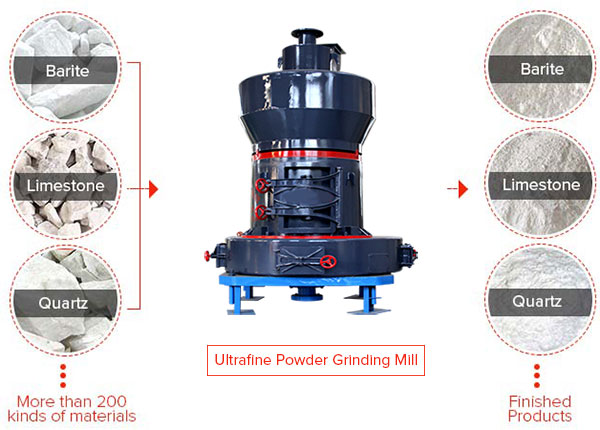

1.HGM superfine powder grinding mill is used to process the non-flammable and non-explosive minerals whose Moh's hardness is less than 9.3 level and humidity is less than 7%.It is the ideal grinding equipment for quartz,feldspar, calcite, limestone, talc, ceramics, marble, granite, dolomite, bauxite, iron ore, bentonite, coal gangue, coal and other over 280 kinds of mining mineral materials.

2.HGM superfine powder grinding mill is a kind of new product with internationally advanced grinding technology which is developed on the basis of our over 20 years powder grinding mill research experience and practical production project and mutual research with German experts to solve the market needs of powder grinding mill.

3.The final product fineness can be adjusted between 0.18mm-0.010mm,namely 80-1250 mesh. Some of the materials' fineness can be up to 2000 mesh at the maxmium.

4.Besides this kind of powder grinding mill, we also have ball mill for powder grinding, which can be used for wet and dry grinding.

1.Higher grinding strength,high production yield,more wide application.

2.Advanced sealing device decrease maintenance costs,prolong the service life.

3.Higher wear resistance,low costs.

4.Product fineness and yield are increased,more accurate regulation,more energy saving.

5.Effective vibration reduction,improve analysis accuration,lower the noise,improving the working environment.

| Model | HGM88 | HGM95 | HGM 100 | HGM120 | HGM130 | HGM138 | HGM160 | HGM175 | HGM190 |

| Feeding size(mm) | <20 | <25 | <25 | <25 | <25 | <25 | <30 | <35 | <40 |

| Finished product size(mm) | 0.25-0.015 | 0.25-0.015 | 0.25-0.015 | 0.25-0.015 | 0.25-0.038 | 0.25-0.038 | 0.25-0.038 | 0.25-0.038 | 0.25-0.038 |

| Processing capacity(t/h) | 0.4-5 | 0.6-7 | 0.8-10 | 1.2-15 | 1.6-21 | 2-25 | 2.7-28 | 3-35 | 5-40 |

| Central shaZD rotate speed(r.min) | 167 | 150 | 142 | 136 | 105 | 92.5 | 82 | 75 | 74 |

| Diameter of pulverizing ring(mm) | 908 | 1006 | 1075 | 1280 | 1400 | 1510 | 1770 | 1900 | 2040 |

| Number Of pulverizing roller | 3 | 3 | 3 | 3 | 4 | 4 | 5 | 5 | 4 |

| Main motor power(kw) | 22 | 30 | 45 | 55 | 75 | 90 | 132 | 185 | 280 |

| Fan motor power(kw) | 22 | 30 | 45 | 75 | 90 | 110 | 160 | 200 | 280 |

| Analyzer motor power(kw) | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 22/30 | 30/45 | 55 |